Annual power generator service is a comprehensive preventive maintenance procedure carried out once a year to ensure reliable and safe operation of the generator. The service typically includes: Visual inspection of the generator, alternator, fuel system, cooling system, lubrication system, control panel, and electrical connections. Oil and filter replacement (engine oil, fuel filters, air filters, coolant filters as required by manufacturer). Battery testing and maintenance – checking voltage, charging system, and replacing worn batteries. Cooling system maintenance – coolant level, hoses, radiator cleaning, and pressure testing. Fuel system check – examining fuel quality, draining water and sediment, checking hoses and injectors. Exhaust and air intake inspection – ensuring no leaks or blockages. Load testing (if required) – verifying that the generator can supply the expected electrical load without performance issues. Control system and safety checks – testing alarms, automatic start/stop function, circuit breakers, and protective devices. Cleaning – removal of dust, oil, and debris to prevent overheating and electrical hazards. The primary purpose of annual generator service is to maximize reliability, efficiency, and lifespan of the equipment while minimizing unexpected breakdowns and costly repairs. Specifically, it ensures: Operational Readiness – the generator will start and run when required, especially in emergency or critical power outage situations. Compliance – maintains adherence to manufacturer’s warranty requirements, safety regulations, and industry standards. Performance Optimization – keeps fuel consumption, emissions, and power output at expected levels. Early Fault Detection – identifies worn or failing components before they cause unplanned downtime. Safety Assurance – prevents hazards such as fuel leaks, overheating, or electrical faults. Extended Equipment Life – proper lubrication, cooling, and cleaning reduce wear and tear on the engine and alternator.

Service Information

-1

Apr 06, 2021

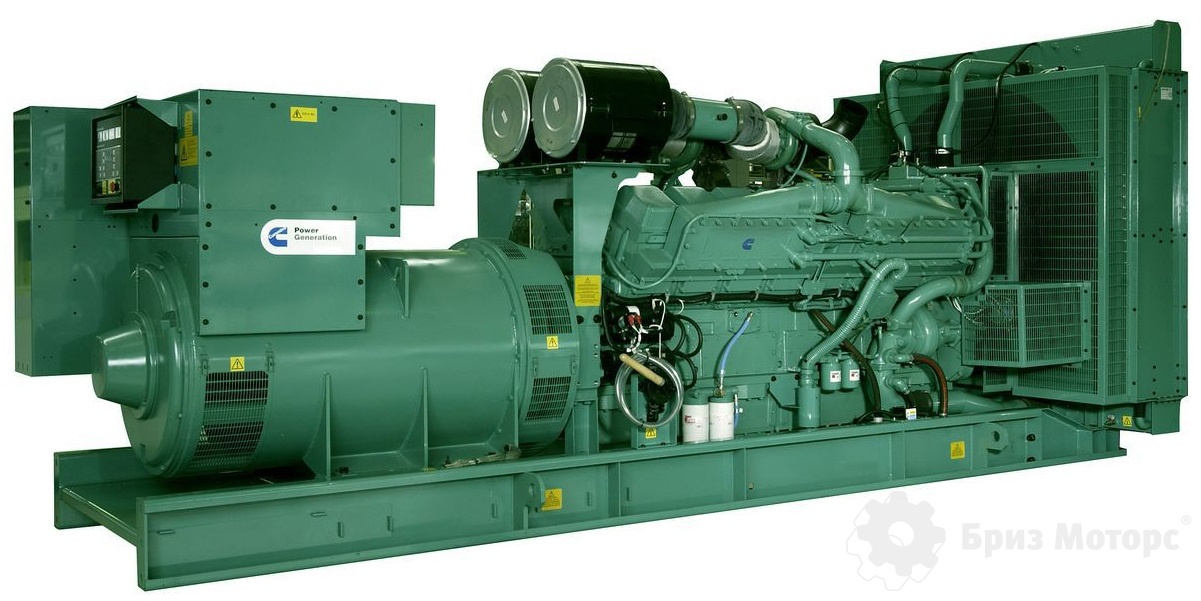

C400D5

A20H013320

Maintenance Schedules

Yearly Maintenance

Next: Aug 19, 2026 (206 days)

Recent Maintenance Records

Recent Repair Records

Apr 03, 2025

Pipe broke from the coolant liquid broke and entire coolant liquid was drained

Zoran Adzic - Cummins

Cost: 58,017.00 RSD